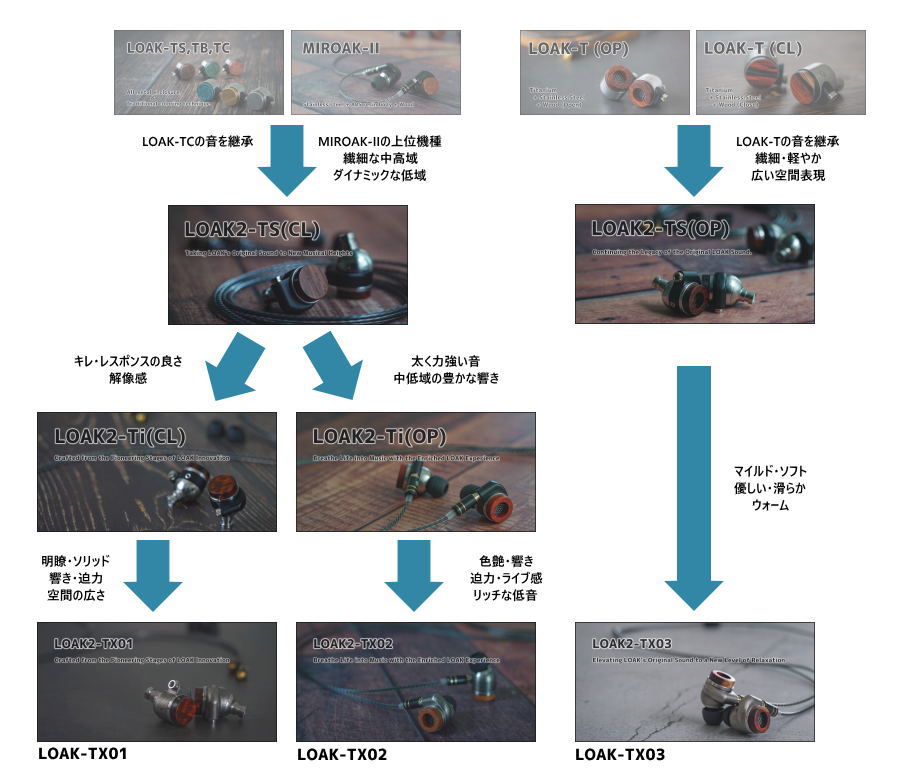

LOAK2-Ti(OP) is a model that has been renewed from LOAK-PROTOTYPE02. In this blog, I’d like to explain the details of LOAK2-Ti(OP), compare its sound with other models, and discuss the wood materials used for the rear housing. For orders and basic information, please refer to the product page below.

Housing)

Front : Titanium.

Body : Titanium(CNC machining) (only MMCX part is resin).

Rear : Various types of wood.

The major change in LOAK-Ti from LOAK-PROTOTYPE01 is in the body housing. We switched from 3D printing to CNC machining. The shape of the housing is the same as LOAK2-TS. While the appearance of the titanium housing resembles stainless steel, titanium tends to develop a slightly darker hue over time.

Right : Titanium

The front housing of the LOAK2 is nearly identical in shape to the previous LOAK, but the internal structure is slightly different, incorporating thin stainless steel in the area where the drivers are secured. While titanium and aluminum are excellent materials for transmitting sound from the drivers to the nozzle tip due to their low vibration damping, they are not as effective at dampening the vibrations of dynamic drivers. Therefore, by incorporating stainless steel into the contact surface of the drivers, we are able to effectively suppress the vibrations of the dynamic drivers and achieve powerful bass and stable sound without distortion.

The MMCX section is designed to be external to the housing that affects sound, and due to its slightly specialized structure, it is made from resin material using 3D printing.

For the open portion of the backplate, we have slightly increased the inner diameter compared to previous OPEN types. This is to slightly reduce the rebound of air inside the rear housing, making the movement of the diaphragm softer and clearly distinguishing it from CLOSED types.

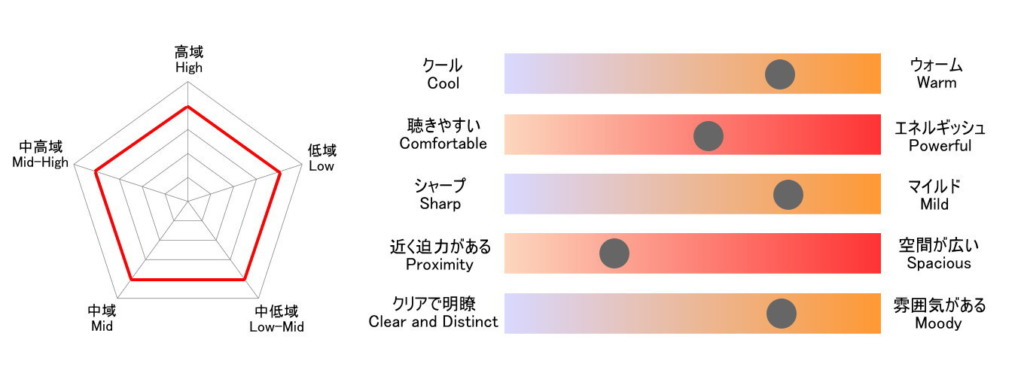

The characteristics of sound and comparison with other models)

The sound tends to be thick, powerful, with a warm tone. It’s the opposite direction of a tight, crisp modern sound, leaning towards a warmer sound.

The tuning remains the same as the old LOAK-PROTOTYPE02 (now LOAK-TX02), but there’s a slight change in sound due to the shift from 3D printing to CNC machining for the housing. Compared to the 3D-printed LOAK-PROTOTYPE02 (now LOAK-TX02), the sound is slightly milder, and it feels like the resonance and reverberation are toned down, leaning towards a more conventional sound.

This is likely influenced by the difference in hardness between CNC machining and 3D printing, even with the same titanium material. Additionally, the transition from 3D printing to CNC machining for the body housing seems to have slightly narrowed the space behind the dynamic driver, affecting the vibration of the diaphragm and resulting in subtle differences in sound.

Comparison of sound with LOAK2-TX02:

LOAK2-Ti(OP) shares the same components as the flagship model LOAK2-TX02 except for the housing, so the sound is generally similar, but TX02 tends to excel in aspects like sound contour, responsiveness, agility, resonance, vibrancy, and overall presence.

While there’s only a slight difference in sound between these two models, with minimal variance in frequency measurements, the richness of sound, luster, and immersive experience elevate the musicality, making the TX02 model feel more lifelike. Conversely, those who prefer a more standard sound without excessive resonance or coloration may prefer LOAK-Ti(OP).

Comparison of sound with LOAK2-Ti(CL):

LOAK2-Ti(CL) and LOAK2-Ti(OP), both featuring the same CNC machined titanium body, have slightly different driver tunings. Ti(OP) adopts a driver design that allows for more air intake compared to Ti(CL), resulting in a larger and more powerful sound due to increased vibration plate movement. Additionally, being open-back, Ti(OP) produces a gentle and relaxed sound due to reduced air pressure inside the rear housing, although this comes at the expense of clarity and sharpness in the sound. On the other hand, Ti(CL) offers sharper and more detailed sound, with tighter bass response.

Ti(CL) delivers a crisp and solid sound, whereas Ti(OP) provides a more relaxed and thick sound. Furthermore, those prioritizing sound clarity, detail, and treble may prefer Ti(CL), while those prioritizing richness, atmosphere, and deep bass may lean towards Ti(OP). These two models are entirely based on personal preference, and there is no superiority between them.

Comparison of sound with LOAK2-TS(OP):

LOAK-TS(OP) and LOAK2-Ti(OP), featuring stainless steel and titanium bodies respectively, have completely different tunings. TS(OP) produces a sound that is thin, delicate, and with very light and clear bass. In contrast, Ti(OP) delivers a thick, powerful sound with a strong presence in the mid-to-low frequencies. These two models can be considered as polar opposites in terms of sound signature.

Regarding the choice of backplate)

Since this model is of the open-back (OP) type, the difference in sound due to the choice of wood and metal for the rear enclosure is relatively small compared to the closed-back (CL) type. Regardless of the chosen material, there is no difference in the sound of LOAK2-Ti(OP), and there is not a significant change that would make it sound like other models. However, upon careful listening, there are subtle differences discernible in the sound.

For those who prefer a tight and well-defined sound, I recommend using hard and dense woods. Ebony or even harder materials would be suitable for this purpose.

If you prefer a slightly mellower sound, it is advisable to choose woods that are not overly hard. Woods softer than rosewood would be preferable.

If you are seeking a lighter and gentler sound, woods with moderate density would be preferable.

I chose African Padauk. While this wood is not particularly hard or dense compared to other woods used by 634EARS, it is one of the few woods where the hardness exceeds the density according to the hardness-density chart. This type of wood tends to have a clear mid to low range and a light feel. In my case, I opted for African Padauk for my LOAK2-Ti(OP) because I was seeking a soft, clear, and airy sound rather than a strong one. The compression of air inside the rear enclosure interacts with the wood (with a nuance closer to absorption), resulting in a slightly softened rebound on the diaphragm, producing a gentle and soft sound.