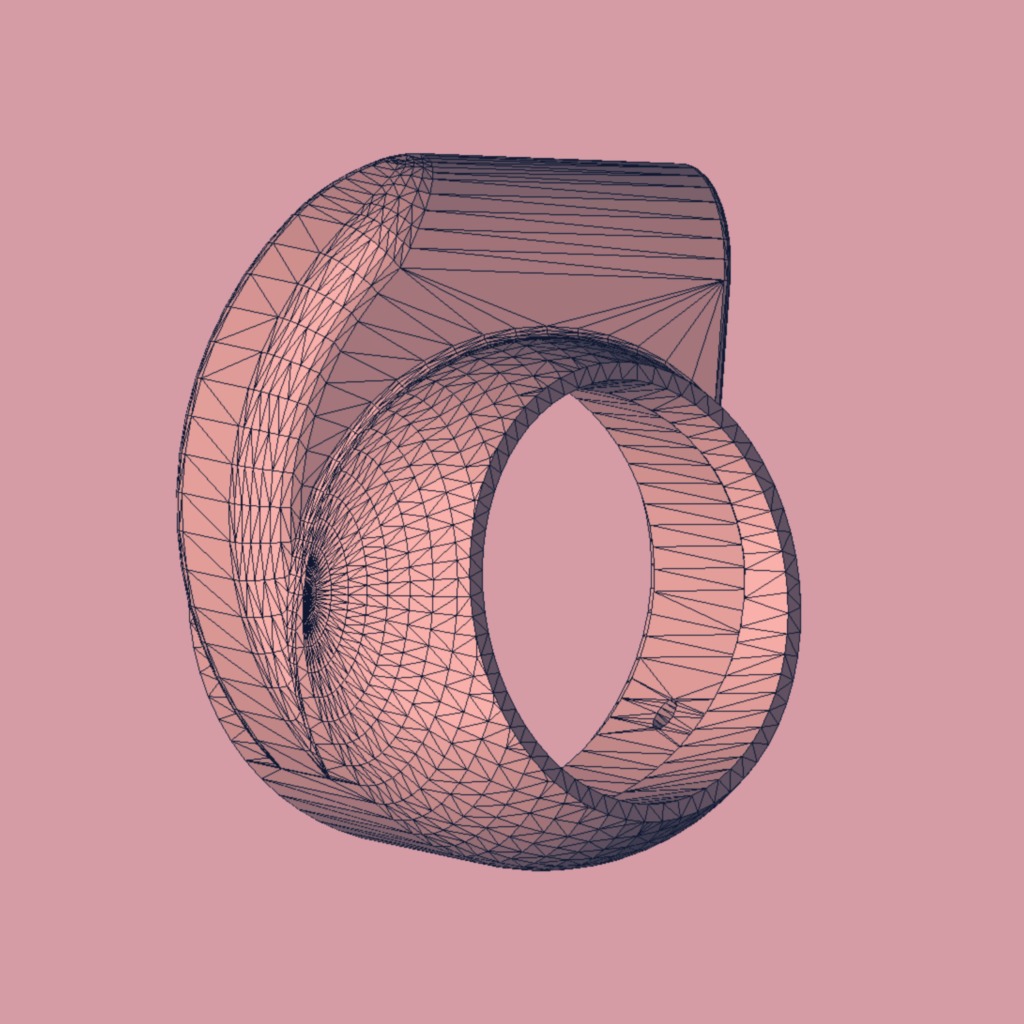

With LOAK completely sold out, we continue the development of the renewed LOAK2 (tentative name). From spring to this summer, we’ve conducted numerous tests on the housing, leading up to actual machining. Initially, we had planned for a titanium 3D print, but it seems unstable, and we still haven’t resolved issues related to post-printing polishing, which leads to dimensional and quality discrepancies, a known weakness of 3D printing.

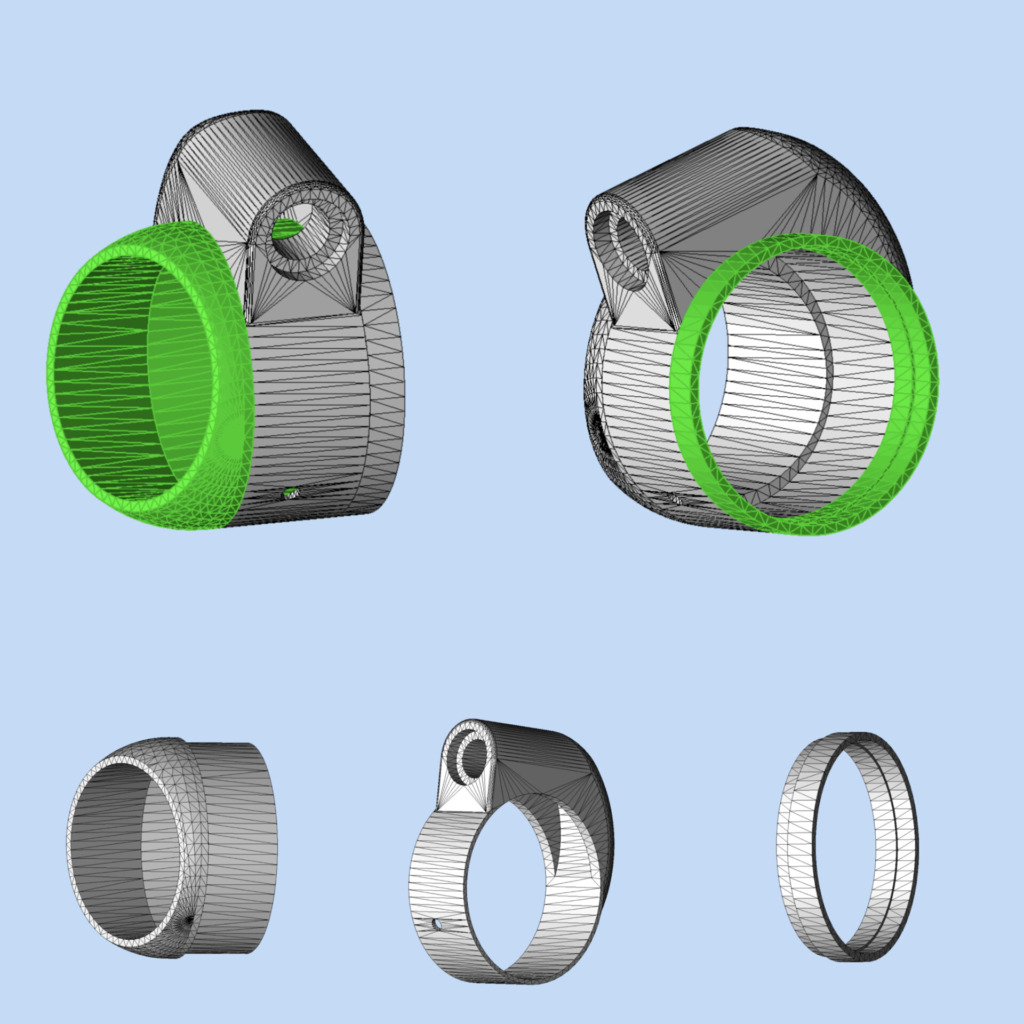

However, machining titanium in complex shapes is challenging, and there are cost considerations related to balancing the cost with the sound quality. Therefore, we are now testing the option of splitting the housing into three parts and machining them from stainless steel or brass materials.

While splitting increases the number of components and costs, it significantly enhances the stability of the product’s quality and expands the available material choices.

To summarize the pros and cons:

Pros of 3D Printing for Housing (in the case of titanium):

Output is straightforward once designed.

Price remains relatively consistent regardless of quantity.

Cons of 3D Printing for Casing (in the case of titanium):

Polishing is necessary (due to the requirement for support structures).

Polishing can slightly alter dimensions.

Quality is less stable due to the need for polishing.

Hardness varies compared to machining (depends on the printing equipment and filament used).

Pros of Machining for Housing:

Dimensional accuracy (can achieve precision within 0.05mm).

Increased material selection.

High dimensional precision, including polishing, ensures stable quality.

Cons of Machining for Housing:

Increases the number of components (complex shapes require splitting).

Increased cost with more parts.

Requires a certain quantity to be cost-effective (in terms of price).

Assembly becomes more labor-intensive due to more parts.

Monolithic titanium 3D printing, segmented machining in stainless steel, brass, aluminum, or resin materials – it’s still uncertain which path I will take. I will continue testing.

Personally, I prefer machining because it allows for thinner constructions and higher precision. However, monolithic titanium 3D printing showed better sound quality than I initially imagined in the prototype phase, so I’m also considering offering both options for a diverse range of products.