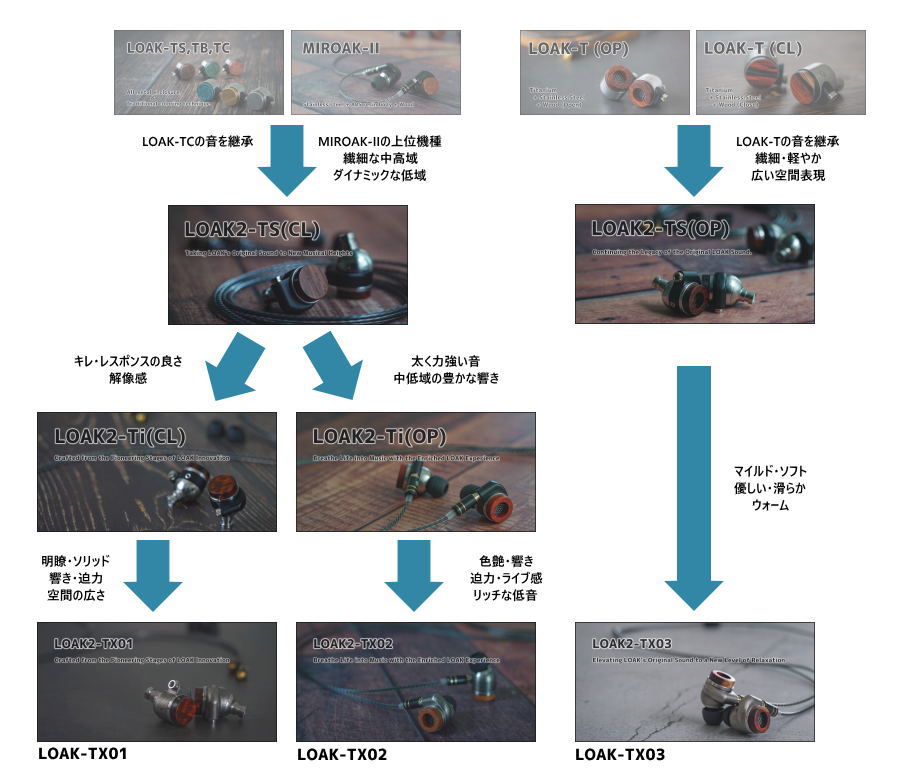

LOAK2-Ti(CL) is a model that has been revamped from LOAK-PROTOTYPE01. In this blog, I would like to delve into the details of LOAK2-Ti(CL), compare its sound with other models, and discuss the rear housing wood options. For orders and basic information, please refer to the product page below.

Housing)

Front : Titanium.

Body : Titanium (only MMCX part is resin).

Rear : Various types of wood, stainless steel, brass, copper.

The major change in LOAK-Ti from LOAK-PROTOTYPE01 is in the body housing. We switched from 3D printing to CNC machining. The shape of the housing is the same as LOAK2-TS. While the appearance of the titanium housing resembles stainless steel, titanium tends to develop a slightly darker hue over time.

Right : Titanium

The front housing of the LOAK2 is nearly identical in shape to the previous LOAK, but the internal structure is slightly different, incorporating thin stainless steel in the area where the drivers are secured. While titanium and aluminum are excellent materials for transmitting sound from the drivers to the nozzle tip due to their low vibration damping, they are not as effective at dampening the vibrations of dynamic drivers. Therefore, by incorporating stainless steel into the contact surface of the drivers, we are able to effectively suppress the vibrations of the dynamic drivers and achieve powerful bass and stable sound without distortion.

The MMCX section is designed to be external to the housing that affects sound, and due to its slightly specialized structure, it is made from resin material using 3D printing.

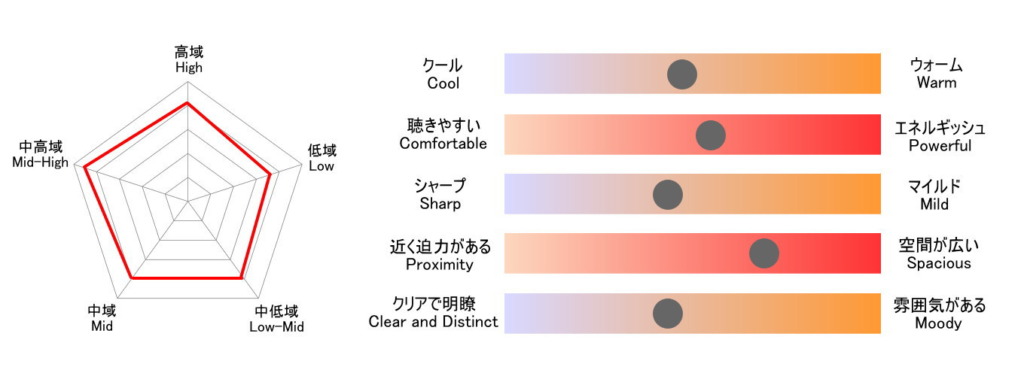

The characteristics of sound and comparison with other models)

It balances sharp, crisp sound with a dynamic mid-bass that has just the right amount of fullness.

Although it shares the same tuning as the old LOAK-PROTOTYPE01 (now LOAK-TX01), the change in the housing from 3D printing to CNC machining has resulted in slight differences in sound. Compared to the 3D-printed LOAK-PROTOTYPE01 (now LOAK-TX01), the sound is slightly mellower, and there seems to be a subdued resonance, leaning towards a more orthodox sound.

This is likely due to the difference in hardness between CNC machining and 3D printing, even though both use titanium. Additionally, the shift from 3D printing to CNC machining for the body housing has resulted in a slightly narrower space at the back of the dynamic driver, which seems to be affecting the sound. These two factors have led to minor differences in the movement of the diaphragm, resulting in subtle differences in sound.

Comparison of sound with LOAK2-TX01:

While the flagship model LOAK2-TX01 shares the same structure as LOAK2-Ti(CL) apart from the housing, they generally have many similarities in sound. However, when it comes to the contours, resolution, speed of response, clarity, lightness, richness of resonance, richness, and spaciousness, LOAK-TX01 feels a step above. Conversely, LOAK2-Ti(CL) offers a more understated, orthodox sound, which may appeal to some preferences.

The difference in sound between these two models is subtle, and there isn’t a significant variance in frequency measurements. However, the beauty of the sound resonance, the richness, and spaciousness of LOAK-TX01 make the music feel more realistic and immersive.

Comparison of sound with LOAK2-Ti(OP):

LOAK2-Ti(OP), with its CNC-machined titanium body, has a slightly different driver tuning compared to LOAK2-Ti(CL). Ti(OP) is designed to intake more air, resulting in larger diaphragm movement and a thicker, more powerful sound. Additionally, being an open-back design, Ti(OP) produces a gentler, more relaxed sound due to reduced air pressure inside the rear housing. As a result, Ti(OP) may lose some transparency and definition compared to Ti(CL); Ti(CL) offers superior sharpness and resolution and a tighter sound compared to Ti(OP).

Ti(CL) delivers a crisp, solid sound, while Ti(OP) offers a more relaxed, robust sound. These differences are purely a matter of preference, and I believe there is no clear superiority between the two.

Comparison of sound with LOAK2-TS(CL):

When comparing LOAK-TS(CL) with a stainless steel body to LOAK2-Ti(CL), TS(CL) delivers a stronger, denser, and sharper sound than Ti(CL). Additionally, TS(CL) feels more closed-off in terms of sound compared to Ti(CL). On the other hand, the titanium body of Ti(CL) offers lightness and a smoother, well-balanced sound. If you seek a powerful, energetic sound, TS(CL) would be more suitable, although it may have slightly sharper peaks in attack and high frequencies. However, for those prioritizing ease of listening, overall coherence, and a balance of power and lightness, Ti(CL) is recommended.

Regarding the choice of backplate)

This model shows significant differences in sound based on the choice of rear housing material or metal compared to the open-back (OP) type. Nevertheless, regardless of the chosen material, the sound of LOAK2-Ti(CL) remains consistent, with no significant changes to resemble other models. However, upon close listening, slight differences in sound can be discerned.

For a tight and crisp sound, I recommend using hard and dense wood materials, such as ebony or even harder ones.

Conversely, for a slightly milder sound, opt for wood materials that are not overly hard. Rosewood or softer woods would be suitable.

For a lighter and slimmer sound, consider using woods that are hard but not excessively dense (woods with hardness relative to density). For example, padauk would be appropriate.

I chose Snakewood. Among wood materials, Snakewood stands out as one of the hardest, resulting in a tight and well-defined sound profile. Additionally, Snakewood is one of the few woods where hardness exceeds density according to the hardness-density table for 634EARS. This type of wood tends to produce clear and defined mid-to-low frequencies, offering a sense of lightness and spaciousness.

Metal materials are also available for selection. You can opt for colored metals by Momentum Factory Orii. Metals are processed slightly thinner than wood and hollowed out at the center to reduce weight. High-rebound materials are installed in the hollowed-out portion. This is because leaving the metal as a solid mass would add weight, and the strong rebound due to compression of air inside the rear housing would make the sound too harsh. Additionally, the high-rebound material installed at the center helps moderate the rebound of compressed air inside the rear housing and also provides moderate absorption, thereby mitigating the strong rebound of air caused by the hard and deformation-resistant metal. This allows the diaphragm to move dynamically without being too tight, resulting in a dynamic and voluminous sound.