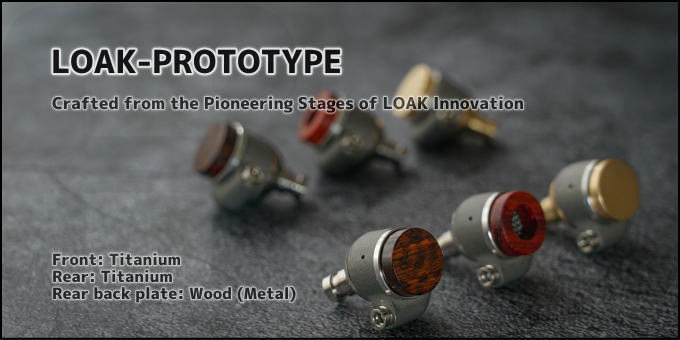

A new LOAK has been released, and I will be posting more detailed information on this blog as it becomes available, but first, let me explain how the LOAK-PRPTOTYPE, released with the LOAK2, came about and what kind of product it is.

1) What is a Prototype?

Normally, the word “PROTOTYPE” is associated with experimental versions or initial prototypes during product development, often giving the impression of something incomplete or flawed.

However, in the case of the LOAK-PROTOTYPE series, “PROTOTYPE” implies a product focused on innovation and challenging the norm while retaining an experimental aspect, rather than being an unfinished product.

2) Development Background.

The LOAK-PROTOTYPE series emerged during the development of LOAK2. To test earphone housings, a series of iterations involving creating, modifying, and recreating prototypes is necessary. The ideal method for such testing turned out to be 3D printing. Unlike traditional methods, 3D printing eliminates the need for molds or metal blocks for machining. All that’s needed are design data, a 3D printer, and filament.

To test sound quality, housings were 3D printed in various materials, including titanium, stainless steel, and various resins. Titanium stood out with its superior acoustic properties. However, titanium is challenging to machine and quite costly. If traditional machining were used, the product’s price would more than double.

On the other hand, 3D printing allows for cost-effective and speedy production. Nevertheless, the process leaves layer marks and support structures that are challenging to remove. Excessive polishing results in a glossy, yet dimensionally altered surface. Achieving uniform polishing across multiple units is difficult, introducing variations.

To address these issues, sandblasting was employed, preserving a textured finish with deliberate layer marks. Even so, variations persisted, with occasional remnants of support structure marks. Consequently, LOAK2 was created by machining stainless steel thinly to match the sound quality of titanium housings.

Despite these efforts, the sound quality achieved with titanium housings was significantly better. Thus, the decision was made to produce LOAK-PROTOTYPE, utilizing select housings that met quality standards while acknowledging that the 3D printing process had certain downsides. Some finishing and edging details were not as refined as those produced through stainless steel machining, but these factors are part of the rationale behind the “PROTOTYPE” name.

3) The Path to Release.

Despite the “PROTOTYPE” label that signifies innovation and challenge, the product maintained a certain level of quality while also having some negative aspects. Consequently, the initial intention was not to release the product.

However, a specific event sparked the idea of selling the product. I love japanese sake and enjoy many different types of sake. I have tasted several of these “prototypes”.

A “prototype” sake is different from conventional ones, using unusual ingredients or methods, being an attempt at a new approach or process for young sake brewers, or tasting differently than before in order to bring a new twist to the market.The goal is to introduce new flavors to the market, deviating from conventional options. They don’t always fit the typical profile, and some may have negative or lacking aspects, but the spirit of experimentation is what makes them appealing.

In the midst of developing LOAK2, the idea was born to release the earphones as LOAK-PROTOTYPE. The sound quality of LOAK-PROTOTYPE was exceptional at that point. While the commitment to continue pursuing new ideas, manufacturing methods, and materials remains, the decision was made not to waste the remarkable progress made along the way.

4) Among the Best Earphones by 634EARS.

Despite the “PROTOTYPE” moniker, LOAK-PROTOTYPE stands as one of the top offerings in 634EARS’ lineup. Rather than getting caught up in the label of “prototype,” we hope you’ll view this product with a positive perspective.