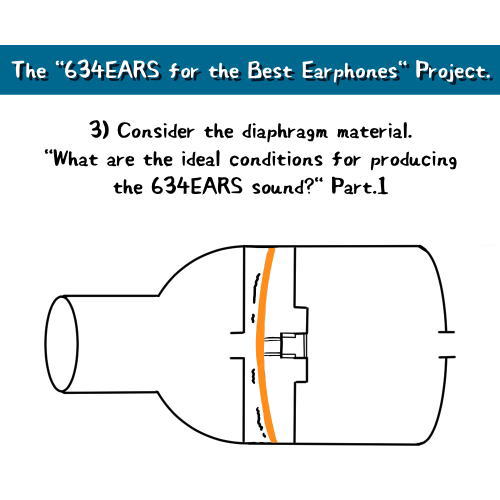

In this article, we will consider the diaphragm material of dynamic-type drivers.

Although the ideal conditions may vary from manufacturer to manufacturer and developer to developer, here we would like to consider what is ideal for the diaphragm as far as 634EARS is concerned.

1) Young’s modulus, density, internal loss.

2) How tunable is sound?

3) Sound tuning range.

1) Young’s modulus, density, internal loss.

Generally, diaphragm materials are required to have “high internal loss”, “low density”, “high Young’s modulus” and “high specific elastic modulus”.

The greater the internal loss, the faster the vibration is absorbed and damped. The opposite is true when the internal loss is small.

Density is just like the word, so you get the idea.

Young’s modulus is the modulus of longitudinal elasticity. Elasticity is the property of a material to return to its original shape after an external force is applied to it.

In 634EARS, wood is often used for the housing material, and hard wood has a high Young’s modulus, while flexible and pliable wood has a low Young’s modulus.

The specific modulus of elasticity is calculated by dividing the modulus of elasticity by the density, and the higher the value, the faster the sound is transmitted.

These are generally required for diaphragms, but not necessarily the only ones in practice.

Some diaphragms are made of metal with low internal loss, and others are made of paper with low specific elastic modulus, so it is difficult to say that the ideal conditions required for a diaphragm are always the best.

Since this is a very difficult subject, I think it is sufficient to recognize that this is what is generally required and to know what each of the required items is.

2) How tunable is sound?

I have already explained what is generally required of a diaphragm, but next I would like to talk about the most important condition for the 634EARS.

The 634EARS does not use the D-type driver as-is, but rather, the D-type driver itself needs to be tuned.

If you just take a finished dynamic driver and stuff it into an enclosure, it is less original, even if the enclosure is the original design.

Of course, the design and materials of the enclosure alone can greatly change the sound, but if the sound can be tuned even for the key D-type driver, the range of sound adjustment is greater, and the probability of reproducing the desired sound with greater originality is higher.

However, some D-type drivers do not allow for a wide range of sound adjustment.

In such cases, no matter how much you adjust the sound with the D-type driver, it can only be tuned within a certain range, and the rate of sound change is low.

So, for 634EARS, the ideal is a D-type driver tuning with a large range of sound adjustment. This is an ideal condition for 634EARS apart from the general ideal condition required as a diaphragm material as mentioned earlier.

3) Sound tuning range.

So what kind of material has the greatest range of sound adjustment?

D-type drivers take in air from the outside (back side) and adjust the movement of the diaphragm.

If the amount of air intake is large, the diaphragm will move widely, and if the amount of air intake is small, the diaphragm will move little.

When the diaphragm movement is large, the sound tends to be thicker, more powerful, louder, and more dynamic and crisp.

When the diaphragm movement is small, it is difficult to obtain a dynamic sound, but the sound is smarter and the sound is more likely to be detailed and resolved.

It is not that one is better than the other, but that the sound varies considerably depending on how much the diaphragm moves.

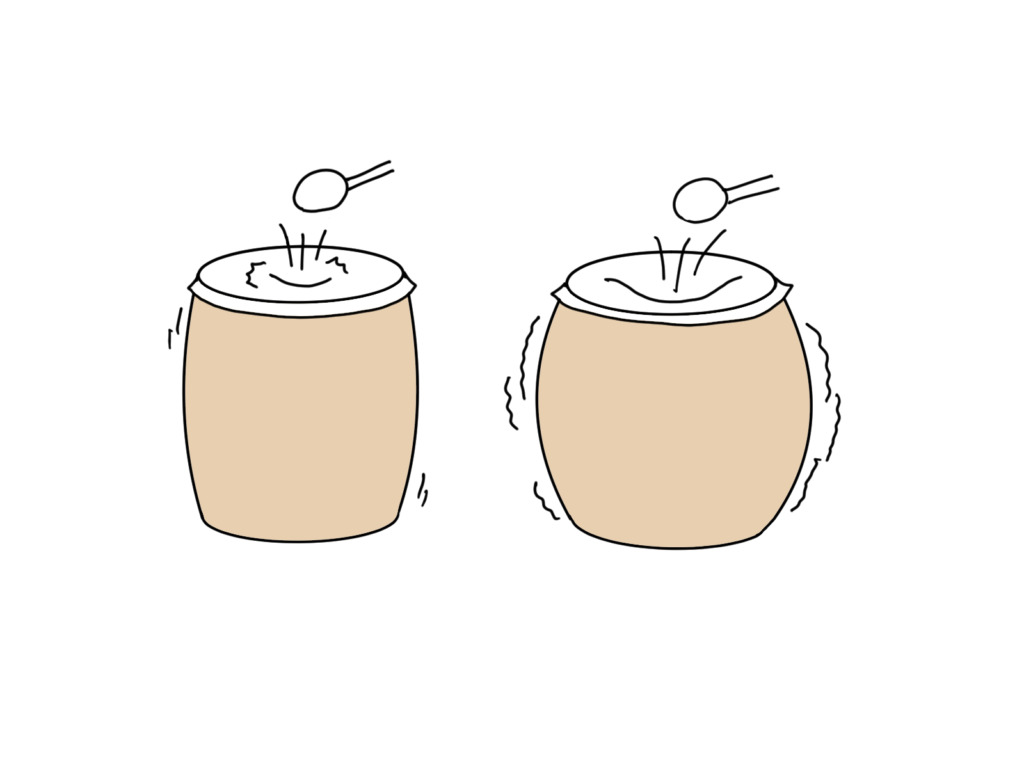

The diaphragm is similar to the head of a drum, for simplicity’s sake. The sound varies depending on the thickness, hardness, and tension of the head.

Even if the thickness, stiffness, and tension of the head are the same, the range of movement of the head will vary depending on the Young’s modulus of the drum shell.

This will be explained in more detail in the rear enclosure material, but you should imagine something like the figure below.

If the shell material is flexible and easily deformable, the head will move significantly. The movement is similar to that of the diaphragm when the air intake is large as described earlier.

If the shell material is hard and hard to deform, the head will move small. The movement is similar to that of the diaphragm when the air intake is small as described earlier.

In other words, it is possible to adjust the amount of air intake of the D-type driver and the material of the rear housing to change the diaphragm’s movement and adjust the sound coming from the diaphragm.

However, if the diaphragm is made of a material that is too rigid and difficult to deform, small, responsive movements are possible, but no matter how much air is taken in or how flexible the material chosen for the rear housing, the diaphragm’s movement will not change much.

The same can be said for thicker diaphragms.

For 634EARS, a diaphragm made of easily deformable material is more likely to produce the desired sound because the greater the range of sound adjustment, the easier it is to tune the sound to the desired level.

However, when seeking an acoustic material with high sound quality, “high internal loss,” “low density,” “high Young’s modulus,” and “high specific elastic modulus” are also necessary conditions, so it is very difficult (because they are contradictory) to select a material with a wide range of sound adjustment.

This is a long story, so I will continue with the diaphragm material in the next article.