I would like to consider in several parts what kind of front housing (mainly material) is suitable for the LOAK upgrade model.

If you have not yet read the following post, which I explained on the same blog last year in thinking about front housing, please go ahead and read it.

I’m going to proceed with this story under the assumption that you’ve read the post above, so if you haven’t, this is your chance!

This issue includes the following four topics

1) Role of the front housing.

2) Nozzle, cup and driver mounting points.

3) What is required of the front housing.

4) Is it possible to split the front housing?

1)Role of the front housing.

The role of the front housing is to reverberate the sound emitted from the D-type driver and emit it as sound from the tip of the nozzle. It is a space and a sound conductor for this purpose.

The diaphragm of the D-type driver emits sound, and the front housing is the component that echoes the sound emitted from the diaphragm and radiates it out of the nozzle.

The point is that the front housing itself isn’t emitting the sound!

2) Nozzle, cup and screwdriver attachment area.

The role of the front housing is actually further divided into smaller roles.

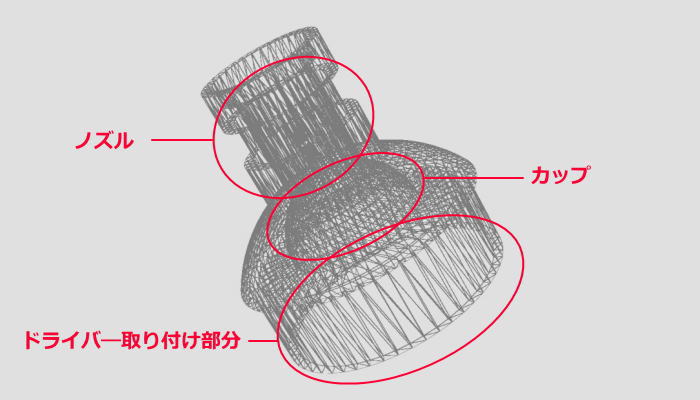

I divide the front housing into three main parts.

I call them “driver mounting area,” “cup,” and “nozzle,” respectively.

それぞれについて簡単に説明します。

a) Driver mounting area.

As the name suggests, this part is where the D-type driver is installed.

What is required of this part is “to suppress the vibration emitted from the D-type driver and fix it firmly in place.

If the vibrations emitted from the D-type driver are not firmly suppressed, the D-type driver itself will not be firmly fixed and will move slightly, resulting in a blurred sound.

On the other hand, if it is fixed too firmly, the vibration may be transmitted directly to the housing and escape.

The D-type driver, which produces vibration (sound), must be firmly fixed in place, while at the same time suppressing vibration in this area, rather than allowing it to escape into the housing.

b) Cup part.

The cup part is the part that makes the sound emitted from the D-type driver resonate (amplify or reverberate).

Some D-type earphones do not have this part at all. If there is no cup at all, the sound from the diaphragm of the D-type driver is transmitted directly to the nozzle.

The shape, depth, and thickness of the cup will affect the sound emitted from the tip of the nozzle.

This part mainly affects the lightness and darkness of the sound, the sharpness and speed of the sound, and the bass.

c) Nozzle part.

The nozzle part is responsible for radiating the sound emitted by the D-type driver and amplified or reverberated by the cup part out of the nozzle.

In doing so, the sound is reverberated (amplified or reverberated) inside the nozzle in the same way as in the cup.

The length, width, material, and thickness of the nozzle affect the tone and resonance of the sound.

This part of the sound varies greatly, mainly in the high frequency range. In particular, there is a change in the attenuation of the ultra-high frequency range, and in the bandwidth and strength of the high-frequency peaks. Also, depending on the thickness and material, the tone of the sound can vary.

3) Front housing requirements.

You have somewhat understood that each part of the front housing has a different required role, but more simply put…

The “driver mounting part that suppresses the vibration of the D-type driver” and “the cup/nozzle part that radiates the sound outward without loss while reverberating it.

But suppressing vibration and transmitting vibration without loss are opposite things, right?

Mm, indeed, the two are opposite in nature. This is a very difficult part of making a front housing.

4) Is it possible to split the front housing?

Then, what if we divide the front housing into three parts, “nozzle,” “cup,” and “driver mounting area,” and make each part from the most suitable material?

Yes, that is the idea. However, there are some disadvantages that arise from splitting the front housing.

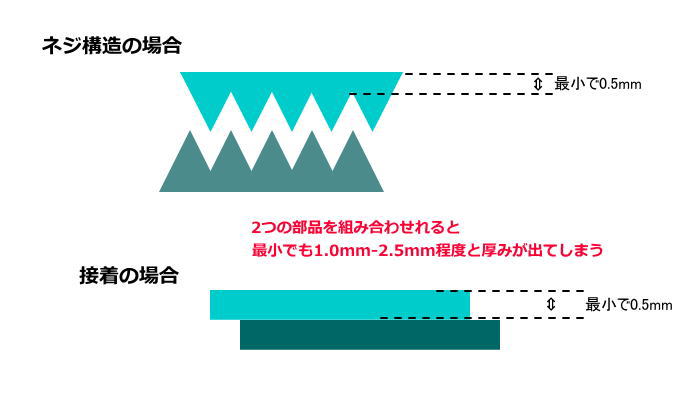

The thickness of the front housing is 0.5 mm at the thin end. This thickness was the limit for strength and workability. Any thinner than this would result in cracking and deformation.

Dividing the front housing into separate parts means that each of the separate parts must be connected (assembled or glued together).

For example, screws have male and female parts, and each part has an uneven surface. Only when these are aligned can they be put together.

If each screw has a minimum thickness of 0.5 mm, the minimum combined thickness is 1 mm. In the case of a screw, the jagged unevenness must be made, so if the concave part is 0.5 mm, the thickness must strictly be greater.

I see, the housing needs to be thicker because of the parts needed to combine the multiple parts to connect them.

Yes. However, the increased thickness of the housing tends to darken the tone of the sound and limits the range in which the tone can be tuned.

It is meaningless to try to produce the desired sound by dividing the front housing into different sections and using the most suitable material for each section, but if the range of sound adjustment is reduced as a result of the increased thickness of the housing, it will be meaningless.

Of course, this would be possible if the D-type driver has a bright sound to begin with or if the tone of the earphones you are looking for is dark, but for earphones like LOAK, this is not possible.

Also, in terms of precision, if one part is divided into three parts, there will be slight deviations in the parts where each part is combined.

Does it mean that the more parts are divided and the number of parts increases, the more the accuracy deviates from that of a one-piece construction?

Yes, and the same is true in terms of cost: one part is often nearly three times the cost of three parts.

Considering these factors, we believe that it would be more beneficial to make front housings in as few copies as possible with as few joints as possible.

This is a bit of a long story, but did you understand the different roles of each part of the front housing and what is required of it?

I will continue this story in the next issue. Next time, I would like to explain the differences in sound for each material.